Autoclave retort machine is a kind of equipment that utilizes high temperature and high pressure for heat treatment of foodstuffs, which is applicable to a variety of packaging forms. According to the sterilization medium and the different forms of structure, the common sterilizer mainly has spray type, water bath type, steam type and so on. For different packaging materials, its heat and pressure will directly affect the quality of products, so the choice of equipment type is particularly critical.

Sterilization of Bagged Products Adaptability

Flexible packaging such as aluminum foil pouches, composite bags are commonly used in sauces, cooked food, leisure food aseptic packaging. This type of packaging pressure resistance is poor, the temperature distribution requirements for uniformity, so it is recommended to use water spray sterilizer retort. This way through the multi-angle cycle of spraying, can avoid packaging bulging or rupture, while maintaining the integrity of the food taste and appearance.

Bottled Products Sterilization Needs

Bottled products such as glass bottles and PET bottles are more susceptible to thermal expansion during the sterilization process. For this type of packaging, hot water circulating or steam retort autoclaves are recommended. Its rapid heating and fine control of temperature difference can effectively prevent bottle rupture and ensure balanced sterilization effect. For liquid foods containing gas or emulsions, a pressure stabilization system is also critical.

Flexibility of Control System and Product Switching

Modern sterilizers are usually equipped with a PLC control system, which allows precise setting of multiple process parameters and one-touch switching to adapt to the sterilization needs of different products. the intelligent retort sterilization machine from Lonkia can preset multiple sterilization formulas and record the operating data to enhance production flexibility and product consistency.

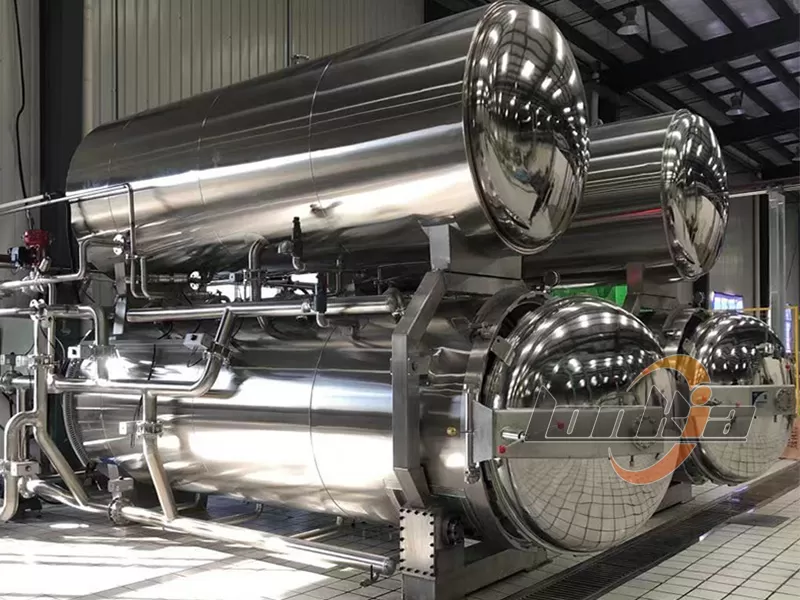

Lonkia Retort Autoclave for Sale

Lonkia sterilizers are highly adaptable, providing a stable thermal sterilization solution whether it is for bagged sauces, canned meat products, or bottled juices and dairy products. Its multi-layer material tray design, high-strength sealing structure and automatic temperature and pressure control system for food processing enterprises to provide high-quality, high-efficiency production guarantee.

In summary, the selection of the right retort sterilization machine should fully consider the type of packaging, heat sensitivity, pressure tolerance and product process parameters. Flexible packaging recommended spray type, bottles suitable for water bath or steam type. Through the scientific selection of equipment models and sterilization methods, not only to ensure food safety, but also to optimize the quality of products and enhance market competitiveness.

If you need to customize the sterilization equipment suitable for your packaging process, welcome to learn about Lonkia's full range of high-performance sterilization pots to help you create a high standard of food processing line.